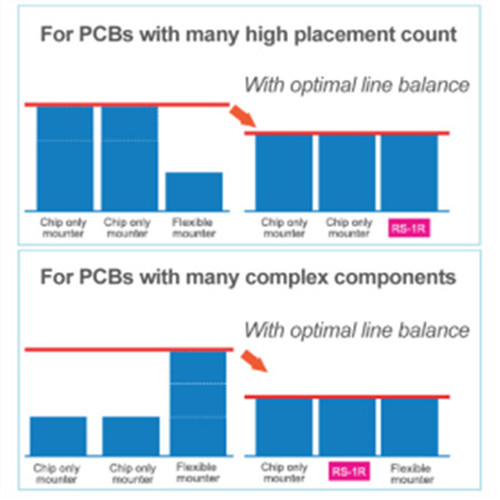

Maximum speed of up to 47,000 cph*. This is made possible by a revolutionary head design that reduces the travel time and distance for every placement.Changing the RS-1 functionality does not require head replacement. The revolutionary design self-optimizes based on the production requirements. The RS-1R can reduce the workload on high speed. A line with two or more RS-1Rs can adjust to a wide variety of production requirements from high speed to high flexibility.

Maximum speed of up to 47,000 cph*. This is made possible by a revolutionary head design that reduces the travel time and distance for every placement.Changing the RS-1 functionality does not require head replacement. The revolutionary design self-optimizes based on the production requirements. The RS-1R can reduce the workload on high speed. A line with two or more RS-1Rs can adjust to a wide variety of production requirements from high speed to high flexibility.

"Takumi head" that automatically optimizes it's height between 6 different positions based on component height. Tact time is optimized by keeping the head as close to the PCB as possible for the components placed.RS-1R supports components from 0201*1(metric) up to 74mm square or 50x150 retangular parts. Component height up to 25mm

"Takumi head" that automatically optimizes it's height between 6 different positions based on component height. Tact time is optimized by keeping the head as close to the PCB as possible for the components placed.RS-1R supports components from 0201*1(metric) up to 74mm square or 50x150 retangular parts. Component height up to 25mm

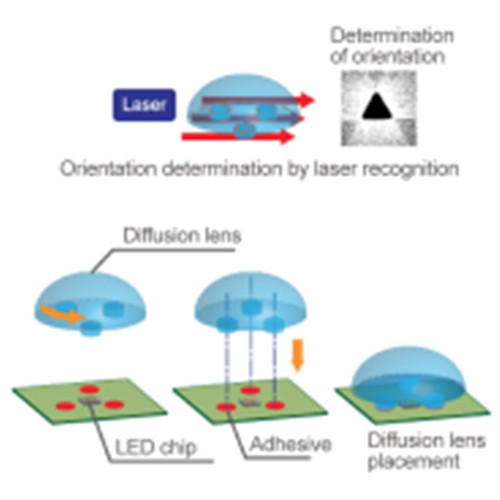

● High-precision placement of diffusion lenses. RS-1R can use either vision or laser centering for diffusing lenses, depending on the component requirements. A wide range of lens styles can be placed.Up to 650 x 370mm with single clamping. LED chip Conveyor direction 2nd clamp placement area ● Long PCB Support Up to 950 x 370mm with dual clamping, or up to 1200 x 370mm with optional conveyor extensions.By measuring the resistance, capacitance or polarity before production starts, the machine can prevent incorrect components from being placed.

● High-precision placement of diffusion lenses. RS-1R can use either vision or laser centering for diffusing lenses, depending on the component requirements. A wide range of lens styles can be placed.Up to 650 x 370mm with single clamping. LED chip Conveyor direction 2nd clamp placement area ● Long PCB Support Up to 950 x 370mm with dual clamping, or up to 1200 x 370mm with optional conveyor extensions.By measuring the resistance, capacitance or polarity before production starts, the machine can prevent incorrect components from being placed.

| Model | RS-1R | ||||

| Conveyor specification | standard | 150mm conveyor extensions, upstream and downstream | 250mm conveyor extensions, upstream and downstream | ||

| Board size | minimum | 50×50㎜ | |||

| maximum | 1buffer | 650×370 ㎜ (Single clamping) | |||

| 950×370 ㎜ (double clamping) | 1,100×370 ㎜ (double clamping) | 1,200×370 ㎜ (double clamping) | |||

| 3buffers | 360×370㎜ | 500×370㎜ | 600×370㎜ | ||

| Component height | 25㎜ | ||||

| Component size | 0201*1 ~□74 ㎜ /150×50 ㎜ | ||||

| Placement speed | Optimum | 47,000CPH | |||

| IPC9850 | 31,000CPH | ||||

| Placement accuracy | ±35μm(Cpk≧1) | ||||

| Vision recognition | ±30μm | ||||

| Feeder inputs | max.112*2 | ||||