New P20 placement head achievesspeeds of up to100,000CPH. At only 998mm wide, the RX-8 provides exceptional productivity in a compact footprint. Best in class placement per square meter(square foot)Component Management with Auto replenishment Top production efficiency is achieved by continuous monitoring of component consumptionand communication with the Automated Component Storage and Transport System. When the placement system detects a low-level warning, it automatically communicates that information to the storage system, which immediately pulls an additional reel of that component, loads it on an AIV to transport the reel to the line to arrive before the existing reel has run out. This eliminates downtime during production due to component run out.

New P20 placement head achievesspeeds of up to100,000CPH. At only 998mm wide, the RX-8 provides exceptional productivity in a compact footprint. Best in class placement per square meter(square foot)Component Management with Auto replenishment Top production efficiency is achieved by continuous monitoring of component consumptionand communication with the Automated Component Storage and Transport System. When the placement system detects a low-level warning, it automatically communicates that information to the storage system, which immediately pulls an additional reel of that component, loads it on an AIV to transport the reel to the line to arrive before the existing reel has run out. This eliminates downtime during production due to component run out.

Trace Monitor provides real time status of the placement head during production. It tracks mis-picks, recognition errors and records which feeders and nozzles those errors came from. A dashboard displays all the key performance indicators makinig it easy to view the production efficiency and what is needed to improve the process.Low Impact feature allows separately adjusting the down and up speed of nozzle during placement. This minimizes the load on the part and on the board during placement. This is optimal for placing very small parts that require a lot of accuracy.

Trace Monitor provides real time status of the placement head during production. It tracks mis-picks, recognition errors and records which feeders and nozzles those errors came from. A dashboard displays all the key performance indicators makinig it easy to view the production efficiency and what is needed to improve the process.Low Impact feature allows separately adjusting the down and up speed of nozzle during placement. This minimizes the load on the part and on the board during placement. This is optimal for placing very small parts that require a lot of accuracy.

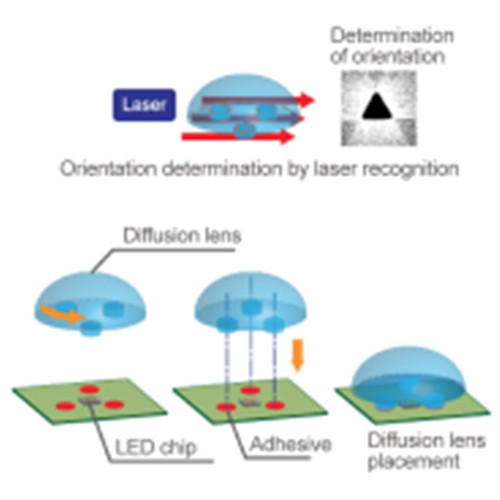

The P20 is designed for placement of ultra-small chips and small IC's. It is ideal for high-density and high-accuracy placement of LED edge lights.The vision system detects presence and absence, inverted chips, and tombstoning. It also automatically corrects the pick position of every part, increasing the pick rate. This system makes it ideal for placing very small parts.

The P20 is designed for placement of ultra-small chips and small IC's. It is ideal for high-density and high-accuracy placement of LED edge lights.The vision system detects presence and absence, inverted chips, and tombstoning. It also automatically corrects the pick position of every part, increasing the pick rate. This system makes it ideal for placing very small parts.

| Board size | 50×50~510mm*¹ *²×450mm | |

| Component height | 3mm | |

| Component size | 0201*³~□5mm | |

| Placement speed (Optimum) | Chip | 100,000CPH |

| Placement Accuracy | ±0.04mm (Cpk ≧1) | |

| Feeder capacity | Upto 56 *⁴ | |

| Power supply | 3-phase AC200V, 220V 430V *⁵ | |

| Apparent power | 2.1kVA | |

| Operating air pressure | 0.5±0.05MPa | |

| Air consumption (standard) | 20L/ min ANR (during normal operation) | |

| Machine dimensions (W x D x H)*⁶ | 998mm×1,895mm×1,530mm | |

| Mass (approximately) | 1,810 kg (with fixed bank)/ 1,760 kg (with bank changing) | |