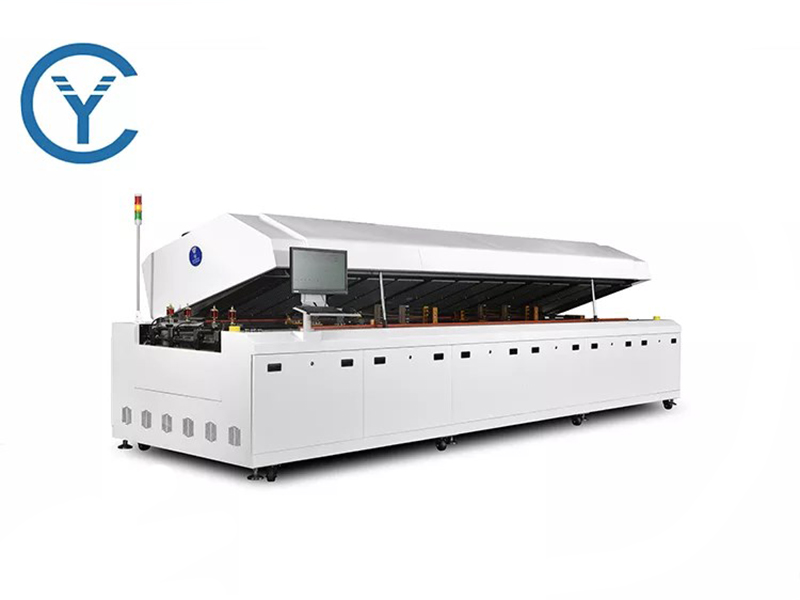

Windows7 operating system, Chinese and English interface switch, easy to operate. Fault diagnosis function, can display each fault, display and store in automatic alarm list Control procedures can automatically generate and backup the data report, easy to ISO 9000 management CY series reflow welding is focused on improving environmental performance of equipment, including a new energy-efficient (duct structure), significantly reducing energy consumption, lower energy consumption and lower carbon emissions

CY series not only meets the highest requirements of lead-free and welding, but also guarantees high quality welding effect, and improves heat conduction technology to avoid overheating of electronic parts on PCB board.