Introduction

In the constantly evolving world of electronics manufacturing, lead-free wave soldering machines have emerged as a significant advancement. As countries tighten their regulations on hazardous substances, the demand for more sustainable and eco-friendly soldering solutions has increased. This blog aims to shed light on the superior configuration and benefits of lead-free wave soldering machines while highlighting the essential role played by the exhaust system in efficiently managing solder and flux emissions.

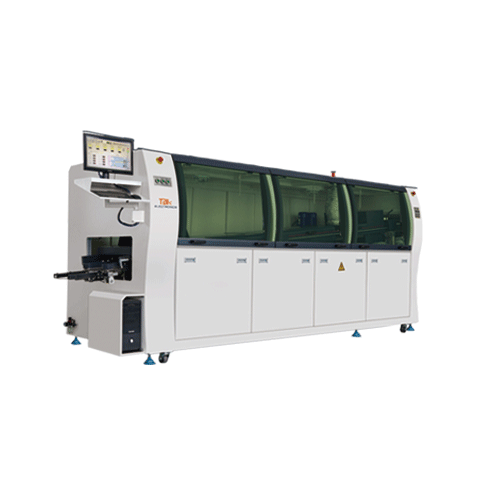

1. Understanding the Lead-Free Wave Soldering Machine

Lead-free wave soldering machines are designed to eliminate the usage of lead-based solder, a toxic material known to be harmful to both human health and the environment. These innovative soldering machines help manufacturers comply with international environmental regulations while ensuring excellent soldering quality.

2. Competitive Configuration and Enhanced Performance

The lead-free wave soldering machine offers a competitive configuration that surpasses traditional wave soldering machines. With advanced technologies and upgraded components, these machines deliver superior performance and results. By optimizing the soldering process, manufacturers can increase efficiency, productivity, and the overall quality of electronic assemblies.

3. The Crucial Role of the Exhaust System

Due to the different composition of lead-free solder and flux, the exhaust system of a lead-free wave soldering machine plays a vital role in ensuring a safe and clean working environment. This system efficiently removes harmful fumes and emissions generated during the soldering process, effectively preventing health hazards for the operators and minimizing the impact on the environment.

4. Benefits of Lead-Free Wave Soldering Machines

4.1 Environmentally Friendly:

The elimination of lead from the solder used in the wave soldering process significantly reduces the hazardous waste generated. By opting for lead-free alternatives, electronic manufacturers actively contribute to a cleaner and healthier planet.

4.2 Compliance with Regulations:

As governments worldwide tighten regulations on hazardous substances such as lead, using lead-free wave soldering machines helps manufacturers stay in line with these environmental requirements. This compliance not only avoids legal consequences but also enhances the brand reputation for responsible practices.

4.3 Safer Work Environment:

The health and safety of workers should always be a top priority. Lead-free wave soldering machines, coupled with the appropriate exhaust system, reduce operator exposure to harmful chemicals, ensuring a safer workplace.

4.4 Improved Product Quality:

Lead-free soldering minimizes the risk of defects and failures in electronic assemblies. By utilizing high-quality lead-free solder alloys, manufacturers can produce reliable, high-performance products that meet the demands of customers and industry standards.

5. Keywords and SEO

Keywords: Lead Free Wave Solder Machine, Environment Friendly, Exhaust System, Solder and Flux, Competitive Configuration.

By incorporating these keywords naturally throughout the blog, it becomes search engine optimized while providing valuable information to readers. For instance, mentioning the importance of a high-functioning exhaust system in countering the challenges of solder and flux emissions in lead-free wave soldering machines emphasizes the unique selling point and differentiates it from the competition.

Conclusion

As the electronics manufacturing industry embarks on a greener and more sustainable path, lead-free wave soldering machines prove to be a game-changer. With a focus on reducing hazardous waste, complying with regulations, and ensuring the health and safety of workers, these machines demonstrate exemplary environmental responsibility. The superior configuration and emphasis on an efficient exhaust system make them the ideal choice for those seeking to combine performance, productivity, and planetary stewardship.