As we progress towards a more technologically advanced era, innovation and automation continue to play a significant role in the manufacturing industry. The production of electronic devices has become increasingly complex, and the demand for precision and efficiency is at an all-time high. This is where automatic PCB soldering machines and dip soldering machines come into play.

Automatic PCB Soldering Machine:

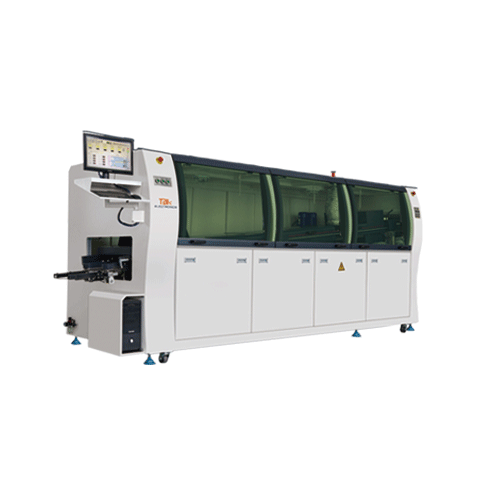

An automatic PCB soldering machine is a fully automated device that is designed to solder electronic components onto printed circuit boards (PCBs). This machine can handle a large number of PCBs at once, providing consistent and accurate soldering in a fraction of the time it would take to do it manually.

The machine's features are designed to ensure that every solder is perfect, and each component is precisely in place. The design minimizes the risks of human error and eliminates the possibility of solder bridges, insufficient soldering, or misaligned components.

Furthermore, an automatic PCB soldering machine is extremely versatile, able to handle different types of electronic components, including Surface Mount Device (SMD) and Through-Hole devices.

Dip Soldering Machine:

Dip soldering machines are used to solder through-hole components onto PCBs. The machine works by dipping the PCB into a bath of molten solder, where the heat causes the solder to melt and form a bridge between the through-hole and the component.

The use of the dip soldering machine is ideal for large-scale production, as it is more efficient than manual soldering. The machine is also designed to eliminate the possibility of solder bridges and increase the quality of the finished product.

In addition, the dip soldering machine has a variety of features that help ensure the precision and consistency of each dip, such as adjustable temperature control, adjustable immersion time, and a motorized lifting mechanism.

Conclusion:

As electronic devices become more complex and their production volumes increase, manufacturers must rely on automated processing equipment to cope with the demand. Automatic PCB soldering machines and dip soldering machines are vital tools in the manufacturing process, delivering top-quality, high-volume production at an optimized cost.

At Shenzhen Jaguar Automation Equipment company, we offer a range of automatic PCB soldering machines and dip soldering machines that will improve your product quality and reduce production time, making them an excellent addition to your manufacturing processes.